GAG vacuum-formed sheet materials are typically made from plastics such as polyurethane (PU), polycarbonate (PC), and polypropylene (PP). During their manufacturing process, glycosaminoglycans (GAGs) may be added to enhance certain properties of the materials.

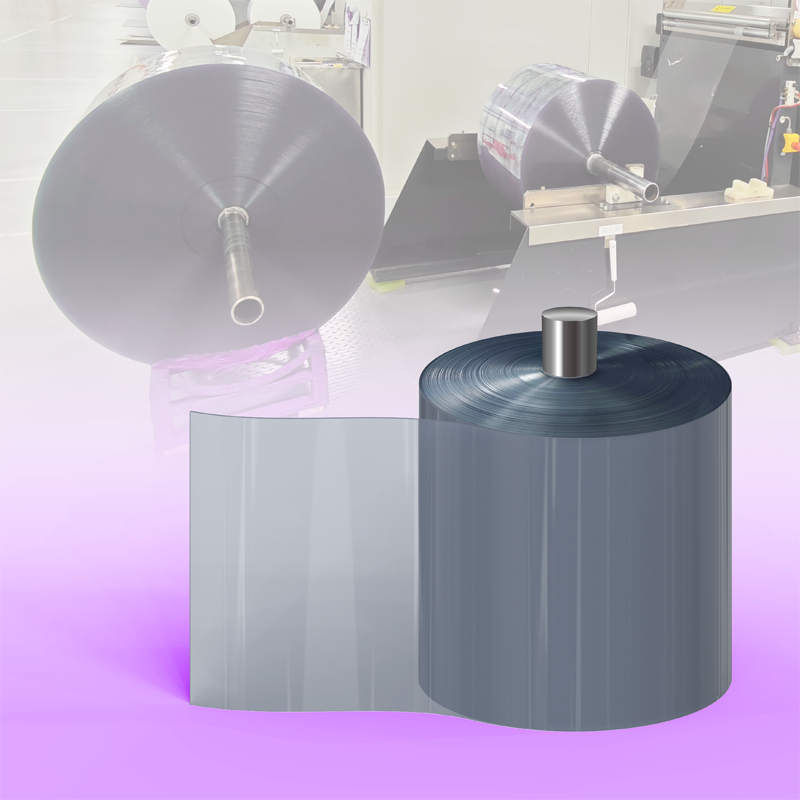

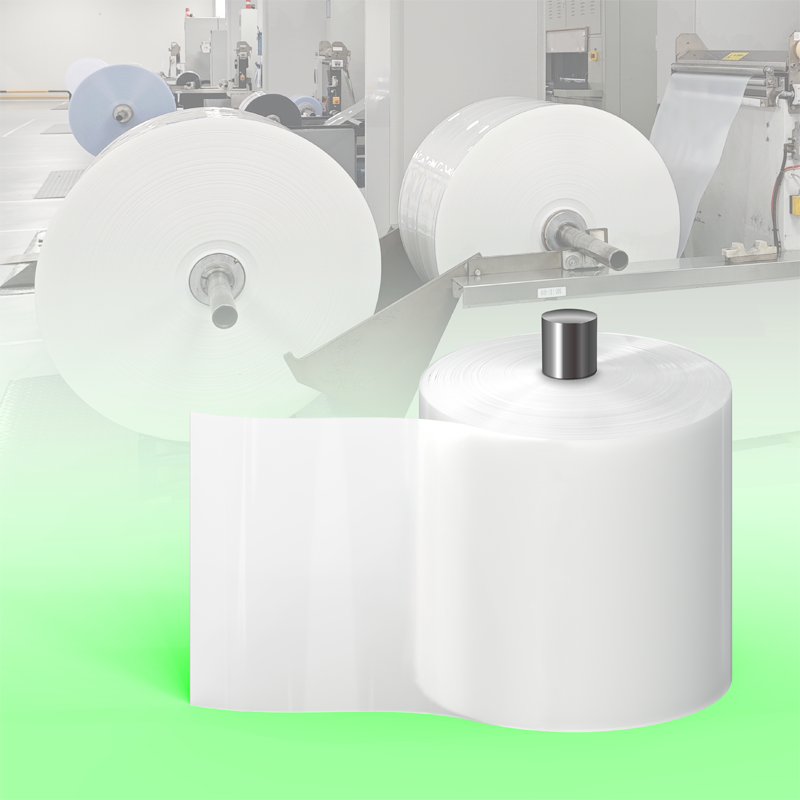

GAG sheet roll

Category: Extrustion Sheet

Our company offers customize, cheap and CE certified vacuum thermoforming sheet roll with high quality, meeting various needs.

Our company offers customize, cheap and CE certified vacuum thermoforming sheet roll with high quality, meeting various needs.

Trgaot is a professional manufacturer of vacuum-formed sheet materials. We produce high-quality GAG plastic rolls and operate a cleanroom compliant with food packaging material production standards. Additionally, we can configure our production facilities to meet the requirements for pharmaceutical packaging with a cleanliness level of 100,000. ZhuoGaoTai is able to respond quickly and meet the needs of both domestic and international clients. Currently, we have established long-term business relationships with many Fortune 500 companies.

Introduction

Advantages of GAG Sheets

GAG sheets offer excellent mechanical strength and toughness. Their surfaces can be treated in various ways, such as spraying, laminating, or printing, to meet different design and functional requirements. Different types of plastic materials, such as polypropylene and polycarbonate, can be selected to achieve specific strength, toughness, and temperature resistance needs. The plastics used in GAG vacuum-formed sheets have good recyclability, helping to reduce environmental impact.

GAG vacuum-formed sheets are widely used across various industries due to their superior formability, lightweight high strength, excellent appearance and surface treatment, and high production efficiency. They effectively meet diverse design and functional needs.

Keywords: GAG sheet roll

Message to Us

master@tragot.com

master@tragot.com

+86 13825096807

+86 13825096807