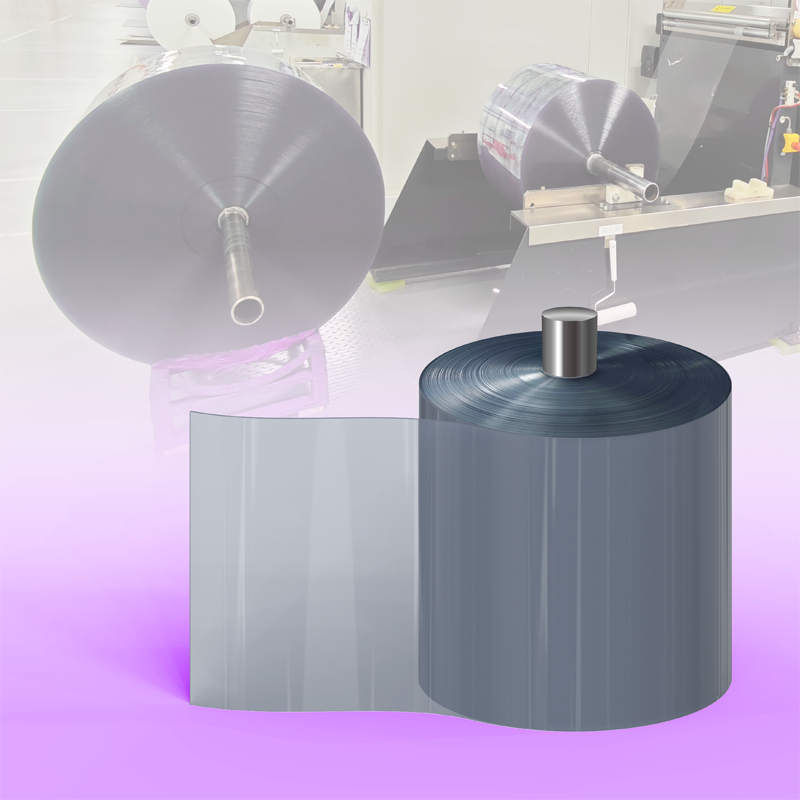

Aluminum-coated PET thermoforming sheet is a composite material that has an aluminum layer deposited onto a polyethylene terephthalate (PET) film. PET, known for its excellent physical and chemical properties, gains enhanced gloss and light-blocking capabilities after aluminum coating. The aluminum layer not only improves the aesthetic appeal of the material but also enhances its barrier performance.

Tragot has comprehensive advanced manufacturing processes for rigid plastic packaging and extensive experience in design and production. Our capabilities include extrusion sheet (single-layer, multi-layer, suitable for integrated FFS machines for filling), thermoforming, injection molding (single-color, multi-color), in blow molding (suitable for healthcare, pharmaceutical packaging), injection-stretch blow molding, and auxiliary processes. These are widely applied in industries such as pharmaceuticals, food, health products, medical devices, automotive, daily chemicals, electronics etc., providing customers with one-stop solution for rigid plastic packaging.

Introduction

Application

Aluminum-coated PET thermoforming sheet has excellent barrier properties, effectively preventing the intrusion of oxygen, moisture, and light, which extends the shelf life of food. It is commonly used to produce food trays, packaging bags, and other food containers.

Advantages

The aluminum coating imparts high gloss and a mirror-like effect to the material, making it visually more attractive. It is often used for packaging and decorating high-end products.

Quality Control

Tragot is equipped with microbiological testing equipment for detecting bacteria, molds, yeasts, and coliforms in products, as well as for testing cleanroom environments. The facility includes a microbiological limit operations room, a positive control room, and monitors cleanroom environment indicators such as dust particles and differential pressure.

FAQ

What thickness options are available for aluminum-coated PET thermoforming sheets?

The thickness of aluminum-coated PET thermoforming sheets typically varies based on specific application requirements, with common thicknesses ranging from 0.2mm to 2.0mm. Custom thicknesses can be provided according to customer needs.

What are the storage conditions for aluminum-coated PET thermoforming sheets?

Aluminum-coated PET thermoforming sheets should be stored in a dry, cool environment, avoiding direct exposure to sunlight and high humidity to maintain their excellent performance.

Purchasing Guide

Next

Keywords: Metallized PET sheet

Message to Us

master@tragot.com

master@tragot.com

+86 13825096807

+86 13825096807