Founded in 1990, Tragot specializes in the design, development, and manufacturing of rigid plastic packaging. With over thirty years of dedication and focus, we have made significant strides in the field of packaging and new materials.

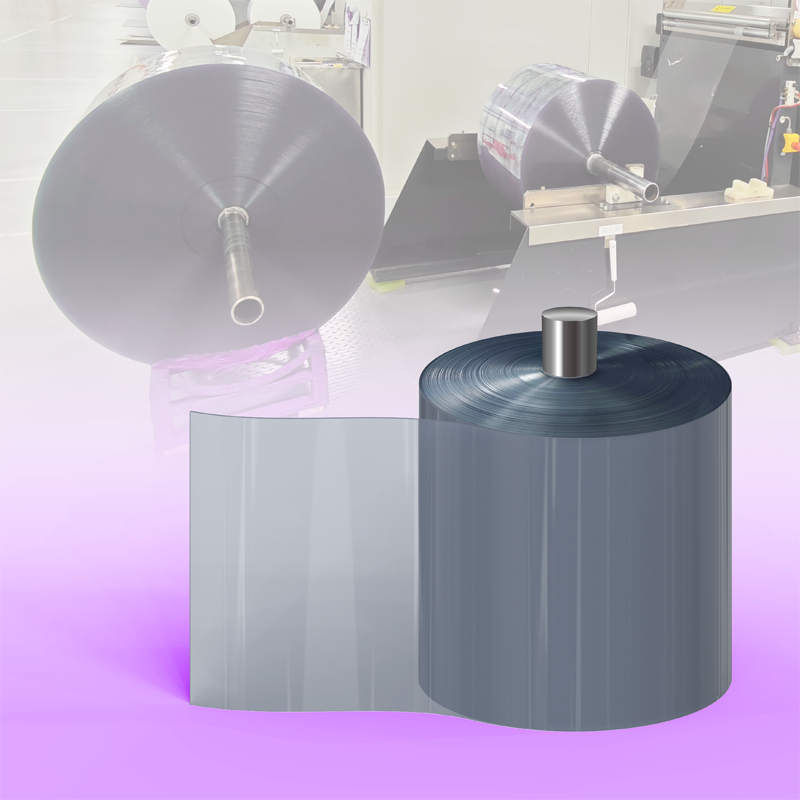

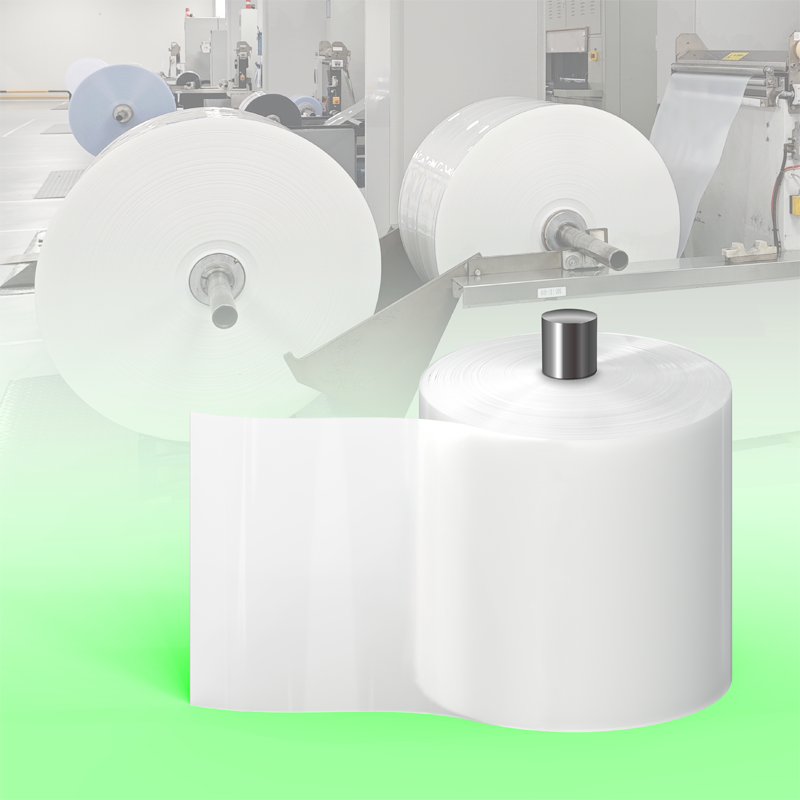

Tragot has comprehensive advanced manufacturing processes for rigid plastic packaging and extensive experience in design and production. Our capabilities include extrusion sheet (single-layer, multi-layer, suitable for integrated FFS machines for filling), thermoforming, injection molding (single-color, multi-color), in blow molding (suitable for healthcare, pharmaceutical packaging), injection-stretch blow molding, and auxiliary processes. These are widely applied in industries such as pharmaceuticals, food, health products, medical devices, automotive, daily chemicals, electronics etc., providing customers with one-stop solution for rigid plastic packaging.

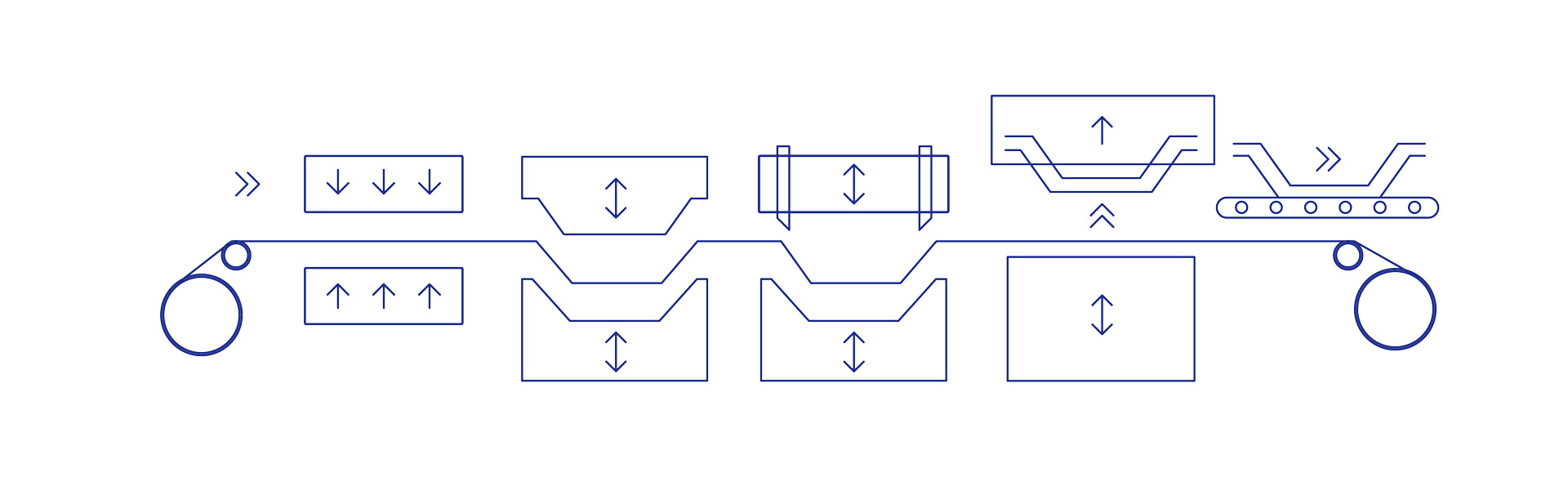

Thermoforming packaging is a process that involves heating plastic materials until they become pliable, then using vacuum or air pressure to mold them into specific shapes on a form. This technique is commonly used to produce trays, containers, and various packaging products. Thermoforming packaging offers excellent protection and sealing properties, making it widely used in food, pharmaceutical, and electronic industries.

Prev

Next

Keywords: thermoformed trays for potato chips

Message to Us

master@tragot.com

master@tragot.com

+86 13825096807

+86 13825096807